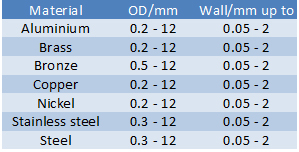

Focus Metals can produce small diameter tubes in all the common ferrous and non ferrous commercial grades from small cut pieces less than 10 mm, or in metre lengths and in long coils. Whilst working at the extreme edge of tube drawing technology, our speciality is supporting our customers at the design and development stage from material selection through to prototyping and eventually to a full production run.

FERROUS TUBES

NON-FERROUS TUBES

Profiles

Focus Metals can produce larger diameter tubing with heavier wall thicknesses to accommodate a wider range of applications for everyday uses. We can advise as to the material, alloy and hardness selection prior to placing an order. To date Focus Metals tubes can be found on the land, under and on the water, in the air and more recently even in outer space

To make your life easier, we offer additional operations to fulfil your tube requirements. Capitalising on years of experience in the industry, we will work with you to establish your needs and then present you with a solution that will satisfy your quality and service expectations. Right first time . . . affordably achieved!

Bending

Our state of the art facilities enable us to bend tubes into complex shapes for all sorts of end applications. For medical, for vehicles, for sports or for science, you can be confident that by working with your engineers from the design and planning stage we will develop a cost effective and high quality solution for you.

End Forming

We understand that the end form of the tube is as important as the alloy itself and is critical for the application you have in mind. We have invested heavily in our end forming capabilities and can produce solutions with even the most complex parameters. This means that the connection between your tube and the next component is nothing short of perfect. As you would expect.

Profiles

Whatever your application, the tube profile is also of paramount importance. Round, triangular, square, pentagon, hexagon or octagon, or more complex shapes – Focus Metals will rise to any challenge.

We invite you to contact us to discuss your specific application and requirements. We are confident that our experience, our technology and our passion for excellence will mean that you enjoy the service, the quality and the partnership that you expect and demand - and that Focus Metals is proud to deliver.

Secondary and tertiary operations are offered by Focus Metals in partnership with Eugen Geyer GmbH.

• Slotting

• Punching

• Drilling

• Knurling

• Flaring

• Telescopic/Sliding fit

• Tipped ends

’One off’ pre-production runs or small sample runs are no problem for us.

Please contact us or send us your technical drawings. We'll be happy to discuss your specific requirements.

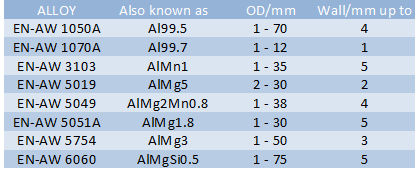

Aluminium is one of the most versatile metals available yet it is one of the youngest. Focus Metals aluminium tubes help you to realise your product objectives be they light weight, damage resistance or just pure strength. The purer grades of aluminium are used for their electrical conductivity, but aluminium also offers good thermal conductivity. Furthermore, due to a specific gravity that is a third of steel, aluminium offers weight advantages. Other alloys available on request.

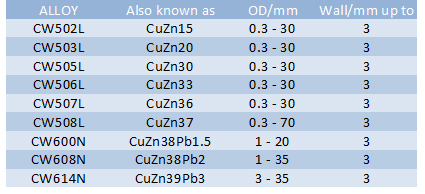

Brass is still and will probably always be an extremely popular metal for general engineering and decorative applications. Focus Metals brass tubes are about more than decoration. The excellent resistance of brass to corrosion means that certain brasses are tolerant of sea water. The addition of lead (Pb) gives the tube characteristics of low friction and wear for excellent machinability.

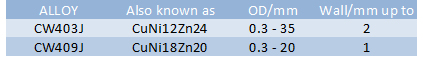

Bronze is a material associated with antiquity, but due to it’s properties it is now found where electronic components and computer-controlled equipment are required. Bronze shows good wear properties and has very good salt water and corrosion resistance. It also offers good spring and friction properties, and has very good fatigue strength and is unaffected by stress corrosion.

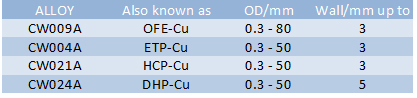

Copper was the first metal utilised by Man. Copper is an extremely flexible metal that offers excellent characteristics that are relevant to modern needs.

The compositions of the various types of copper are not solely due to the purity, but also to the presence, or lack of oxygen, which performs a special function with copper. A low oxygen content assists in negating trace impurities and therefore increasing the electrical conductivity

Pure nickel (99.6%) and the iron-nickel alloys show very high corrosion resistance and have many applications at elevated temperatures. The chemical and food industries make use of these properties. Furthermore, the very low thermal expansion coefficient allow these alloys to be used for electro-ceramic and glass-to-metal seal components.

Amongst all metals, stainless steel is perhaps the most versatile. From the extreme working environments of the aerospace and oil extraction industries to temperature monitoring equipment and medical instruments, Focus Metals stainless steel tubes can be found everywhere. The high temperature and corrosion resistance along with a bright surface finish make this an engineer’s choice for most applications. The lower Carbon content alloys are suitable for welding.

Although not having the corrosion resistance as stainless steel,

mild steel nevertheless plays a very important part in our everyday life. Due to its strength and relatively lower cost, it is used for general engineering purposes, leisure products (bicycle frames) and through to the construction industry.

(c) Focus Metals Limited 2022 | All Rights Reserved.